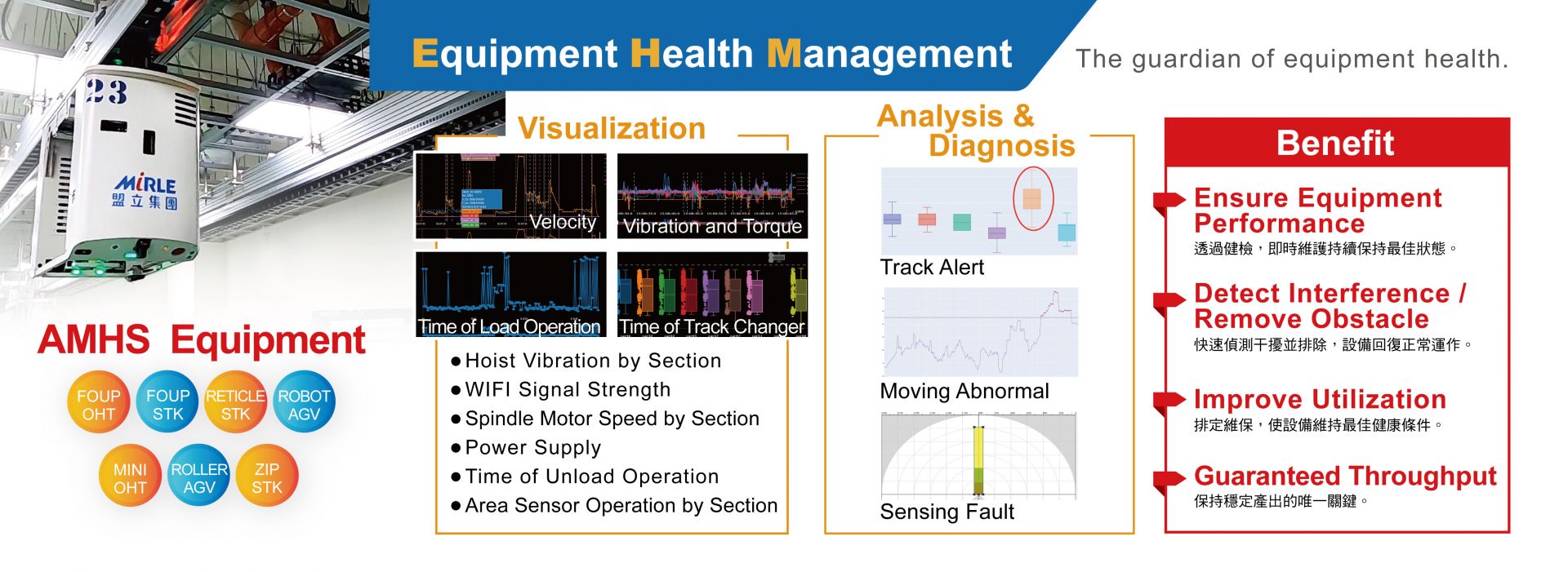

EHM covers functions of inspection, diagnosis, and prediction of equipment health, which lays the crucial foundation of digital transformation and digital decision-making for manufacturers.

EHM is the guardian of equipment vitality, ensuring peak performance and maximizing productivity. It's not just a tool; it's your partner in achieving unparalleled operational efficiency. Elevate your manufacturing capabilities with EHM — where innovation meets maximum capacity.

EHM encompasses the three crucial stages of a product lifecycle—production inspection, equipment setup assessments at the client site, and continuous inspection throughout the maintenance phase.

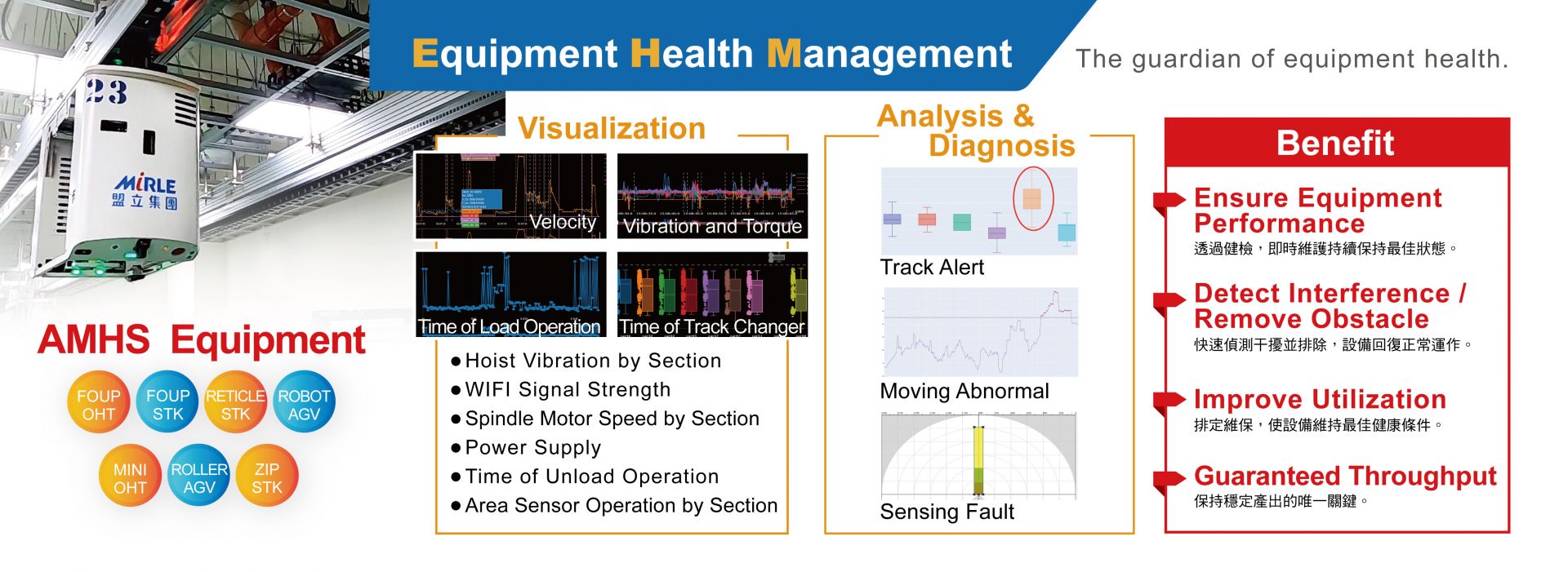

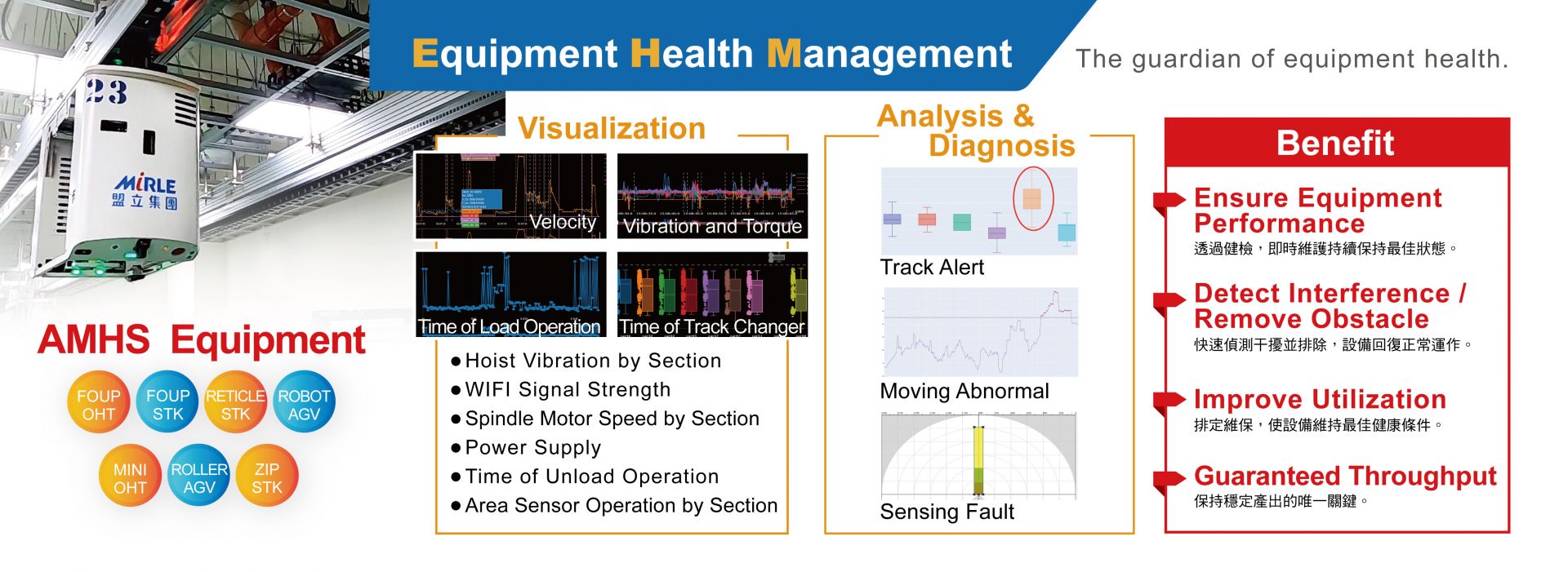

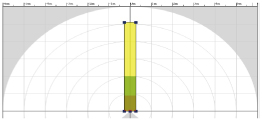

Visualization

- Hoist Vibration by Section

- WIFI Signal Strength

- Spindle Motor Speed by Section

- Power Supply

- Time of Unload Operation

- Area Sensor Operation by Section

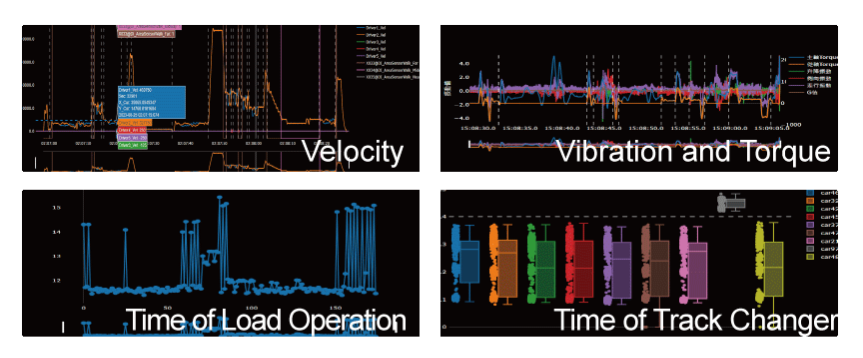

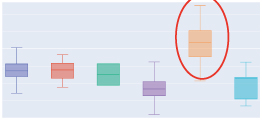

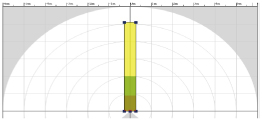

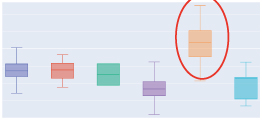

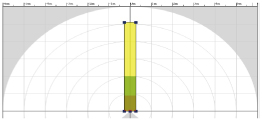

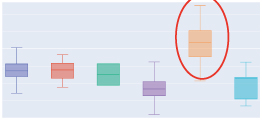

Analysis & Diagnosis

Track Alert Moving Abnormal Sensing Fault

Benefit

- Ensure Equipment Performance

- Detect Interference/Remove Obstacle:abnormal interference occurs, causing a decrease in operational efficiency, EHM can quickly detect, identify, and resolve the error, returning equipment to regular operation. For example, wireless signal interference causes communication abnormalities.

- Improve Utilization:helps to prevent equipment’s sudden failure. Through IPM, it predicts potential failure times, schedules maintenance, ensuring optimal equipment health.

- Guaranteed Throughput:Ensuring stable production output hinges on the real-time monitoring of equipment health and operational status. This key factor involves optimizing equipment performance.

Mirle EHM ( Equipment Health Management): the Guardian of Equipment Health

EHM covers functions of inspection, diagnosis, and prediction of equipment health, which lays the crucial foundation of digital transformation and digital decision-making for manufacturers.

EHM is the guardian of equipment vitality, ensuring peak performance and maximizing productivity. It's not just a tool; it's your partner in achieving unparalleled operational efficiency. Elevate your manufacturing capabilities with EHM — where innovation meets maximum capacity.

EHM encompasses the three crucial stages of a product lifecycle—production inspection, equipment setup assessments at the client site, and continuous inspection throughout the maintenance phase.

Visualization

- Hoist Vibration by Section

- WIFI Signal Strength

- Spindle Motor Speed by Section

- Power Supply

- Time of Unload Operation

- Area Sensor Operation by Section

Analysis & Diagnosis

Track Alert Moving Abnormal Sensing Fault

Benefit

- Ensure Equipment Performance

- Detect Interference/Remove Obstacle:abnormal interference occurs, causing a decrease in operational efficiency, EHM can quickly detect, identify, and resolve the error, returning equipment to regular operation. For example, wireless signal interference causes communication abnormalities.

- Improve Utilization:helps to prevent equipment’s sudden failure. Through IPM, it predicts potential failure times, schedules maintenance, ensuring optimal equipment health.

- Guaranteed Throughput:Ensuring stable production output hinges on the real-time monitoring of equipment health and operational status. This key factor involves optimizing equipment performance.