With over 30 years of expertise in intelligent manufacturing integration in industries such as FPD and semiconductors, Mirle Group excels in simulation planning, project management, problem-solving, and after-sales service. This comprehensive capability enables Mirle Group to provide customers with efficient and reliable MCS(Material Control System).

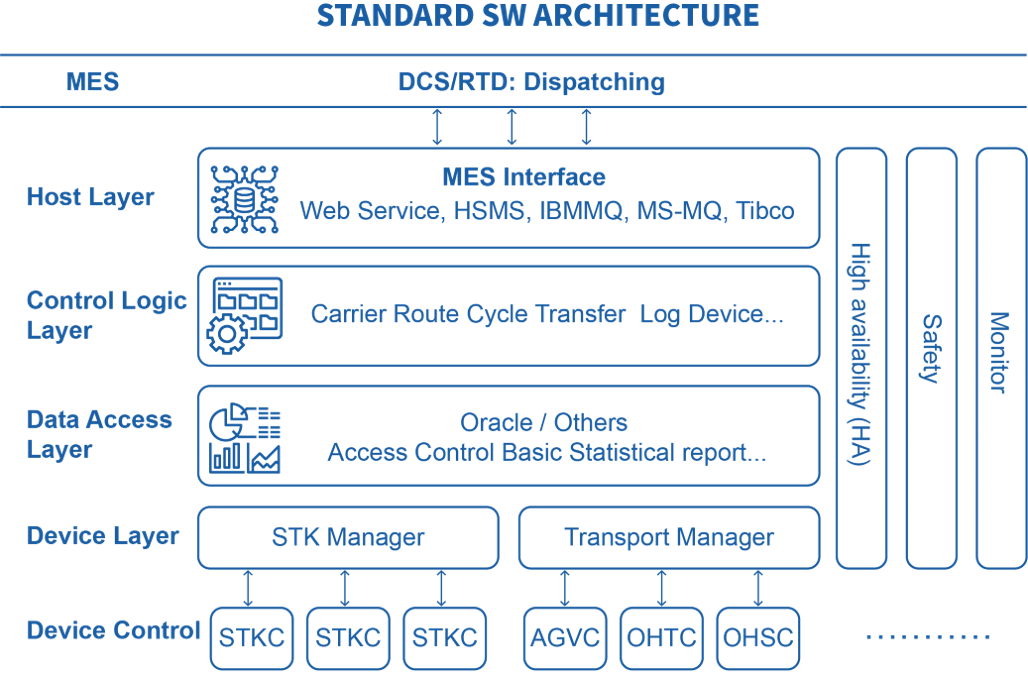

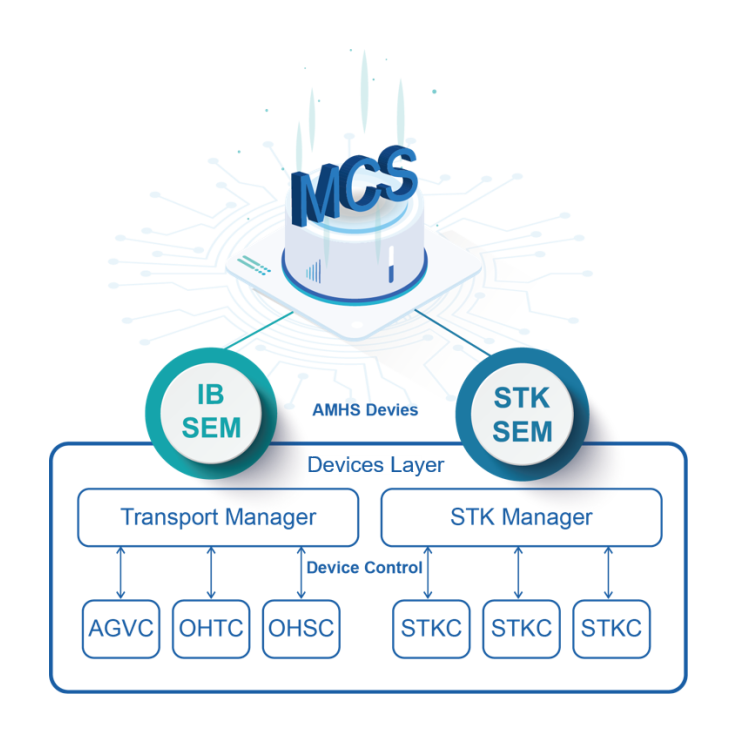

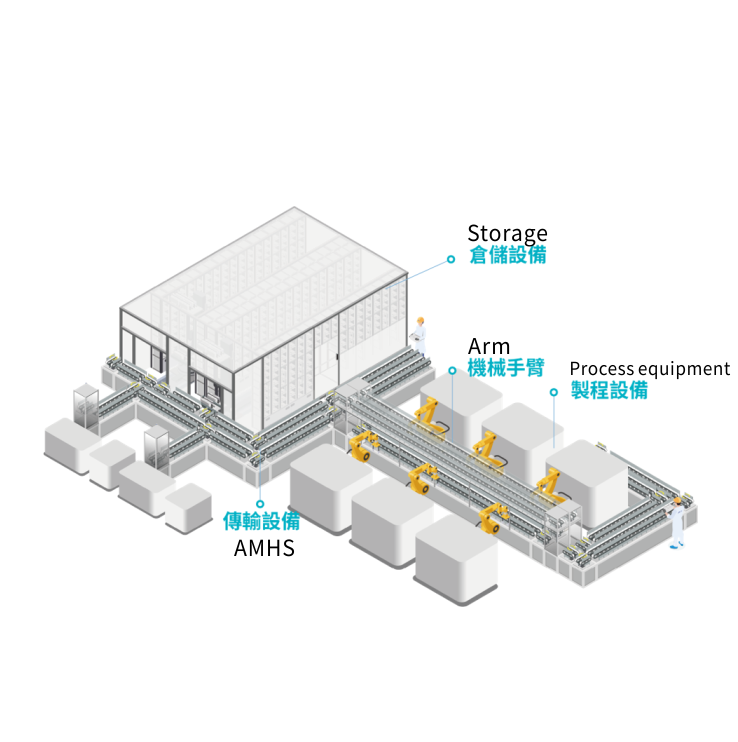

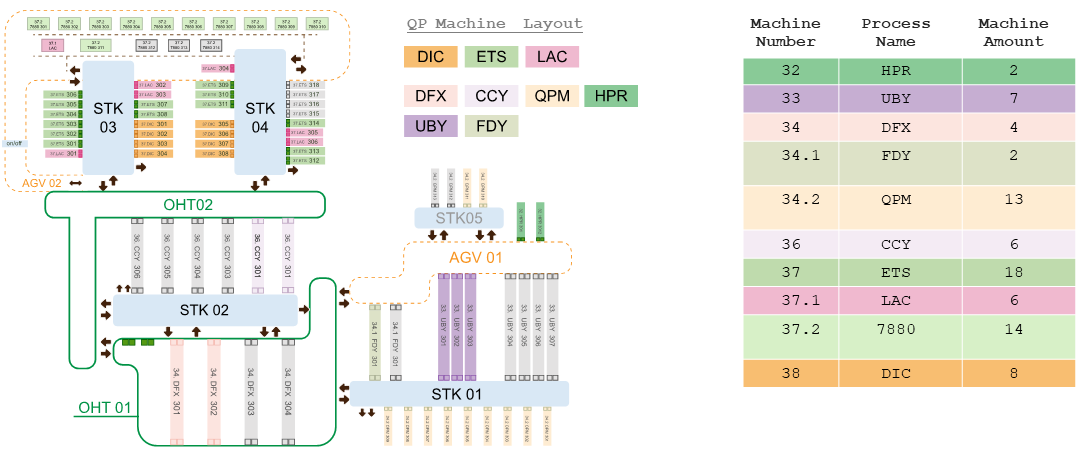

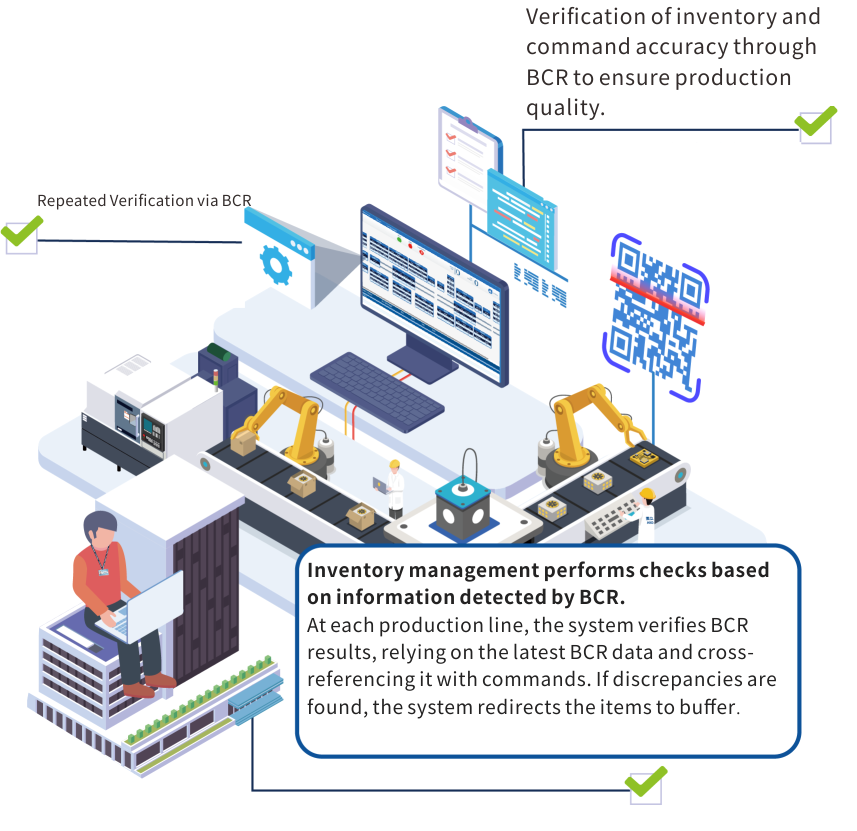

The Material Control System (MCS) plays a crucial role in the material handling of intelligent factories. The Manufacturing Execution System (MES) issues transport commands to the MCS, which monitors the status of all equipment in the factory. The MCS selects the optimal route for material delivery, reducing transfer times and enhancing the efficiency and utilization of factory equipment.

Features of MCS:

Mirle's MCS is a high-performance, mature, and stable system featuring an easy-to-use human-machine interface. The system allows users to query and adjust equipment status, historical data, vehicle usage status, and inventory management details. It provides an overview of the entire factory's logistics system.