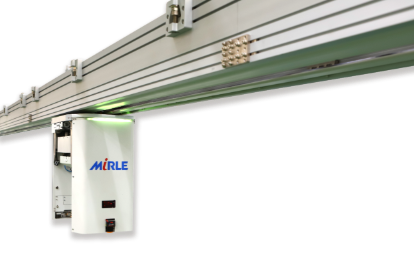

The OHT system is a ceiling-suspended automated transport solution that utilizes the vertical space above process equipment. Tracks and lift mechanisms are installed above equipment, with customizable lengths ranging from hundreds of meters to several kilometers.

Designed to meet customer needs, the system enables seamless transport of FOUPs or glass cassettes across different production zones or even between separate buildings. Unlike conventional systems that rely on stockers as intermediaries, the factory-wide OHT system supports direct EQ-to-EQ transport, significantly reducing transfer time and production cycle time.

OHT is widely adopted by small- to medium-sized TFT-LCD panel manufacturers both domestically and internationally for the automated handling of glass substrates and LCD panels in production lines.

-

Mini OHT

Load capacity: 15kg. Ideal for backend semiconductor facilities with low ceilings.

Carrier Types: Magazine/CST.

Key features: Low height, wireless power supply, cleanroom compliant, low vibration.

-

OHT V6

Load capacity: 12kg. Suitable for front-end semiconductor environments.

Carrier Type: 12" FOUPs.

Key features: High efficiency, low vibration, high reliability. SEMI-compliant.

-

OHT 40

Load capacity: 40kg. Designed for backend semiconductor processes.

Carrier Type: 510x515mm panel-level packaging.

Key features: High load capacity, wireless power, low vibration, cleanroom compatible.

Customized OHT Vehicles and Routing Solutions

To meet the specific requirements of the LCD and semiconductor industries, Mirle provides customized OHT vehicles compatible with a variety of carrier types, including LCD panel trays, FOUPs, metal cassettes, magazines, and JEDEC trays.

By integrating advanced AutoMod simulation tools and flexible track design, Mirle delivers optimal path planning and logistics strategies during the early deployment phase. The system's intelligent software control logic helps prevent vehicle collisions, deadlocks, and idle time due to queuing, thereby significantly improving throughput and equipment utilization.

The mechanical design features non-contact power transmission (HID) and low-particulate components, meeting stringent cleanroom standards in environments ranging from Class 10 to Class 100.